No Waste

No loss of product due to human error, especially where little or no colour variation exists between phases.

Detection

Detects and retains or rejects valuable interface materials containing recoverable products.

Safety

Serves as a safety device on effluent discharge systems reducing and/or eliminating pollution problems.

Automatic

Requires minimal attention, service and maintenance thereby reducing labour costs drastically.

Stainless Steel

Standard body materials of construction are either carbon steel or stainless steel, in both cases the internals are constructed from stainless steel.

Here is a brief selection of some organisations that have benefitted from using the coveted Belfield Valve. Be sure to be one of them.

Discover more about the unique Belfield Valve today with the launch of our online brochure. It includes detailed information about its performance and applications which best suits this industry leading decantation valve.

Belfield Valve

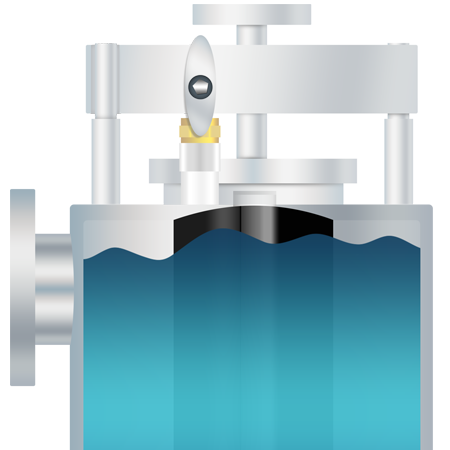

Ballasting the float. The float is ballasted by adding water via the hexagon headed screw in the top of the float to give the float positive buoyancy in the heavier liquid and negative buoyancy in the interface or lighter liquid, as required.

Belfield Valve

Need more information on how the Belfield will be ideal for your particular application?