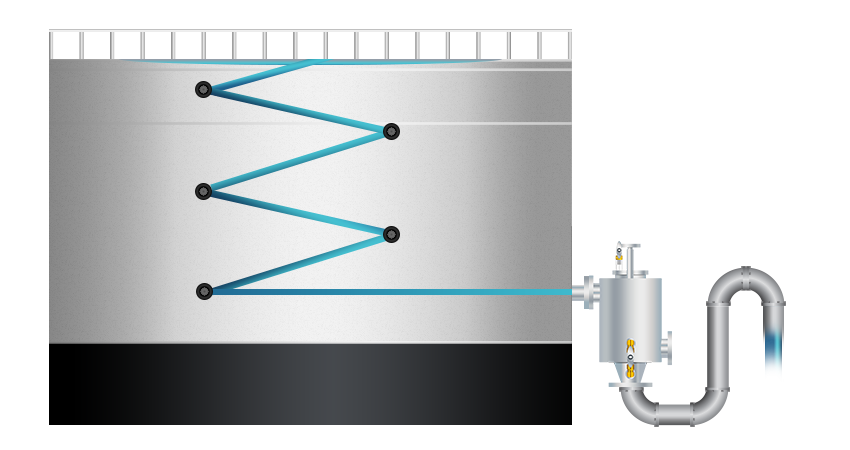

Floating Roof Tank Solution

Solutions designed for every refinery.

To address this problem a Belfield valve may be used on the drain connection at the tank side. The Belfield valve with the optional “swan neck” outlet is designed to allow the valve to stay open whilst water is present whether flow or not. This is affected by allowing the outlet from the valve to be full all the time whilst not being allowed to siphon. The float therefore floats all the time and if a rain event happens, the valve allows the rain to flow from the roof to via the internal drain mechanism and out through the Belfield valve. In the event of a leaking joint or drain hose the Belfield valve will sense the changing gravity and close. This avoids the potential of allowing product to go to drain or contaminate the ground and expensive recovery processes.